- Home

- ETC Library

- Steering Gear Service

The Steering Gear & Lubricants

This article is the result of an e-mail request for information from a member. He needed lubricant for the steering gear of his ’38 Pontiac, but finding it proved to be a problem. He asked for my recommendation, I checked back to see what I had previously written and then decided to investigate the situation further. I have new recommendations, and this article will explain why I have made them.

According to Pontiac parts and service information, all ETC-era automobiles with manual steering used a worm and roller (wheel) type steering gear. The worm gear is part of the steering shaft/column and the roller is atop the end of the Pitman shaft. The exposed end of the Pitman shaft mounts the Pitman arm, which connects with the remaining steering linkage and the front wheels. The steering gear is essential to proper handling and ease of driving in our vintage Pontiacs. If it is worn or improperly adjusted, driving will be a chore, not the pleasure that it should be!

Based upon the internal components, from 1937 on, all of our cars with manual steering share the same steering gear; although the housing differed to suit the chassis it was installed on. Again, based upon the components, all of our cars from 1939 forward shared the same steering linkage, the link-parallelogram system. I have pointed out before that Pontiac’s steering system was very advanced, and remained in use into the 21st century in light truck applications. Modern automobiles have nearly all gone to a power-assisted rack and pinion steering gear; without the power assist, rack and pinion steering is not well suited to a large, heavy vehicle.

The power steering gear Pontiac used in 1953-54 was not the familiar worm and roller, it was the new recirculating-ball type, with the power cylinder attached but separate. The steering gear section was filled with steering gear lubricant while the power cylinder section was lubricated with the same Hydra-Matic fluid the power steering unit was filled with. The recirculating-ball type steering mechanism ultimately became the standard Saginaw configuration for General Motors manual steering boxes in later years. It offers very smooth and precise steering action via the use of many individual ball bearings contained in its mechanism.

Regardless of the model year or type of steering gear, they all need to be filled with the proper lubricant. Early Pontiac automobiles included an oil gun in the tool kit for use by the owner, according to the owner’s manual, their Pontiac required chassis lubrication every 500 miles. The oil used was usually 600W steam cylinder oil, which is still available today. Heavy “weight” automotive gear oil was also suitable. You can imagine that using heavy oil in the steering linkage was a messy proposition; it constantly dripped out of all the joints. It was not long before grease became the lubricant of choice, suspension components were fitted with Alemite or Zerk fittings to accept the appropriate type of high-pressure grease gun. This allowed lubrication intervals to be increased; grease is somewhat solid and not prone to dripping, so it remained in place far longer then heavy oil. This arrangement worked fine for the king pins, suspension bushings and tie rod ends, but not for the steering gear mechanism.

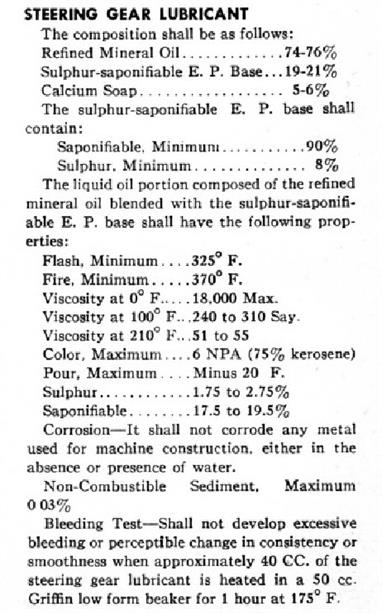

The steering gear needed a more specialized mixture to insure proper lubrication of its finer mechanism. The early, light cars got along fine with 600W oil; but as the vehicle size and weight increased, so did the load on the steering gear. By the mid-30’s, an extreme pressure additive was necessary in the steering gear lubricant to protect components from premature wear. The following formula was taken from the 1940 Pontiac service manual, and provides us with a solid starting point for our new lubricant.

This article is the result of an e-mail request for information from a member. He needed lubricant for the steering gear of his ’38 Pontiac, but finding it proved to be a problem. He asked for my recommendation, I checked back to see what I had previously written and then decided to investigate the situation further. I have new recommendations, and this article will explain why I have made them.

According to Pontiac parts and service information, all ETC-era automobiles with manual steering used a worm and roller (wheel) type steering gear. The worm gear is part of the steering shaft/column and the roller is atop the end of the Pitman shaft. The exposed end of the Pitman shaft mounts the Pitman arm, which connects with the remaining steering linkage and the front wheels. The steering gear is essential to proper handling and ease of driving in our vintage Pontiacs. If it is worn or improperly adjusted, driving will be a chore, not the pleasure that it should be!

Based upon the internal components, from 1937 on, all of our cars with manual steering share the same steering gear; although the housing differed to suit the chassis it was installed on. Again, based upon the components, all of our cars from 1939 forward shared the same steering linkage, the link-parallelogram system. I have pointed out before that Pontiac’s steering system was very advanced, and remained in use into the 21st century in light truck applications. Modern automobiles have nearly all gone to a power-assisted rack and pinion steering gear; without the power assist, rack and pinion steering is not well suited to a large, heavy vehicle.

The power steering gear Pontiac used in 1953-54 was not the familiar worm and roller, it was the new recirculating-ball type, with the power cylinder attached but separate. The steering gear section was filled with steering gear lubricant while the power cylinder section was lubricated with the same Hydra-Matic fluid the power steering unit was filled with. The recirculating-ball type steering mechanism ultimately became the standard Saginaw configuration for General Motors manual steering boxes in later years. It offers very smooth and precise steering action via the use of many individual ball bearings contained in its mechanism.

Regardless of the model year or type of steering gear, they all need to be filled with the proper lubricant. Early Pontiac automobiles included an oil gun in the tool kit for use by the owner, according to the owner’s manual, their Pontiac required chassis lubrication every 500 miles. The oil used was usually 600W steam cylinder oil, which is still available today. Heavy “weight” automotive gear oil was also suitable. You can imagine that using heavy oil in the steering linkage was a messy proposition; it constantly dripped out of all the joints. It was not long before grease became the lubricant of choice, suspension components were fitted with Alemite or Zerk fittings to accept the appropriate type of high-pressure grease gun. This allowed lubrication intervals to be increased; grease is somewhat solid and not prone to dripping, so it remained in place far longer then heavy oil. This arrangement worked fine for the king pins, suspension bushings and tie rod ends, but not for the steering gear mechanism.

The steering gear needed a more specialized mixture to insure proper lubrication of its finer mechanism. The early, light cars got along fine with 600W oil; but as the vehicle size and weight increased, so did the load on the steering gear. By the mid-30’s, an extreme pressure additive was necessary in the steering gear lubricant to protect components from premature wear. The following formula was taken from the 1940 Pontiac service manual, and provides us with a solid starting point for our new lubricant.

I sent this formula to a major oil refinery prior to my last oil and lubrication article, at that time they had no compatible product available, and no recommendation. I recommended 2 industrial gear oils by name; Hector oil or Inca oil. A recent check on the refiner’s websites revealed that both of these products are now obsolete, so another recommendation is obviously required.

The basis for my steering lubricant recommendation is Pontiac’s stated requirements in service literature, in addition to the 1940 service manual formula. The service manual description from 1940 is for a “light non-flowing lubricant that has a temperature range from extreme summer conditions to below zero without affecting the efficiency of the steering gear.” This is almost a contradiction in terms; “light non-flowing lubricant” defines grease; but the base mineral oil viscosity shown in the 1940 formula is far below current base oil viscosity numbers. Today’s refining process is far advanced from what existed in 1940. It is now possible to have higher viscosity numbers and still achieve flow at extreme low temperatures. Therefore, my recommendation is based more upon the minimum flow temperature than the base oil viscosity, especially since few, if any, of our members will be driving their car at 20 below zero! Instead of using high viscosity gear oil, I have been looking at light grease.

The National Lubricating Grease Institute (NLGI) rates the viscosity of grease using a number scale from 000 to 6. Anything below 0 actually exhibits a semi-fluid characteristic. Our lubricant needs to be thin enough to insure lubrication of every component, but thick enough to prevent leakage past the Pitman shaft seal. This is especially true for the ’53-’54 recirculating-ball mechanism. I believe NLGI 00 is our number. If your car were to suffer leakage with 00, you could easily specify the 0 grade of that same grease, which will not flow.

The basis for my steering lubricant recommendation is Pontiac’s stated requirements in service literature, in addition to the 1940 service manual formula. The service manual description from 1940 is for a “light non-flowing lubricant that has a temperature range from extreme summer conditions to below zero without affecting the efficiency of the steering gear.” This is almost a contradiction in terms; “light non-flowing lubricant” defines grease; but the base mineral oil viscosity shown in the 1940 formula is far below current base oil viscosity numbers. Today’s refining process is far advanced from what existed in 1940. It is now possible to have higher viscosity numbers and still achieve flow at extreme low temperatures. Therefore, my recommendation is based more upon the minimum flow temperature than the base oil viscosity, especially since few, if any, of our members will be driving their car at 20 below zero! Instead of using high viscosity gear oil, I have been looking at light grease.

The National Lubricating Grease Institute (NLGI) rates the viscosity of grease using a number scale from 000 to 6. Anything below 0 actually exhibits a semi-fluid characteristic. Our lubricant needs to be thin enough to insure lubrication of every component, but thick enough to prevent leakage past the Pitman shaft seal. This is especially true for the ’53-’54 recirculating-ball mechanism. I believe NLGI 00 is our number. If your car were to suffer leakage with 00, you could easily specify the 0 grade of that same grease, which will not flow.