Service parts and maintenance

The accompanying parts listing was compiled from the Pontiac Oakland Master Parts catalog dated 10-1-40; the ’48 Wholesale Parts catalog; the ’53 Master Parts catalog and the ’55 Master Parts catalog. We have listed all of the Early Times era part numbers under each heading, including the pre-war and post-war numbers, were applicable. Where latter numbers superseded former ones, these appear on the note line with an (S).

N.O.S. (new, old stock) parts are still relatively easy to find and could be used to complete a restoration, especially if you do not intend to drive the car very much. If you want your vintage Pontiac to be really road-worthy, you should probably have the water pump professionally rebuilt using new parts, not N.O.S. items.

Obviously the “packed” pumps offer minimal opportunity for improvement, but any ’33 or newer Pontiac six or eight would certainly benefit from the use of the “packless” design with brand new bearings and seals installed. One issue essential to either type of water pump is the amount of clearance between the impeller blades and the inner surface of the pump housing. The better the bearing, the closer the allowable clearance; but for maximum pumping capacity you want the impeller as close to the housing as you can get it without contact. The tips of the impeller blades are also critical for best operation. They should be relatively square and conform well to the surface of the housing; just because an impeller is new, does not mean that it is any good. A poor casting is a poor casting, period. Design tolerances vary, but I prefer to see no more then about .040” maximum between impeller and housing, you can easily check it with a wire-type spark plug gapping tool. Again, position the impeller as close as possible to the inner housing. Assuming the blade tips are well shaped and stand at the same height, you can simply press the impeller further onto the shaft to close the gap. Be certain to recheck the clearance carefully after each “adjustment”.

There are 3 items of concern for the “packed” pump; proper adjustment of the packing nut, lubrication of the bushings and tension of the fan belt. It is essential for maximum life of the packing material that a slight amount of seepage be allowed; this water cools and lubricates the packing. If the packing nut is tightened excessively, the packing will become burned or glazed and ultimately fail. It is also very likely to score or wear the shaft to the point that, it too requires replacement. Replacement packing material should be scarf-cut at 45 degrees with a new, single edge razor blade. Be sure the ends do not align as each piece of packing is put into the housing. Rotate the shaft as you tighten the packing nut to be certain the packing does not bind it tight. I would allow a steady drip when the engine is first started; add water as necessary and run the engine until you have it up to operating temperature. You can continue to gently snug the packing nut without causing damage, but if you have the nut too tight to begin with, the packing will probably be ruined almost immediately.

The Durex bushings originally installed by Pontiac should be lubricated with light engine oil, they recommended S.A.E. 10W. If your pump was professionally rebuilt, be sure to use what the rebuilder recommends with regard to lubricant. Pontiac also recommended to their dealers that new bushings be kept soaking in oil prior to their installation and use, this insured the bushings remained saturated with oil. Upon installation, the factory bushings had to be reamed to size. The appropriate clearance with the shaft is .0005” to .002” and this will require very careful fitting on your part. It will also require a good straight reamer. The smoother and straighter the bushings are reamed, the better the operation and longevity of the pump.

The final adjustment that can greatly impact the life of these pumps is fan belt tension. The belt needs to be tight enough to prevent slippage, but that is all. Excessive belt tension aggravates wear on bushings and the shaft, and also can lead to leakage from the packing. Belt tension is much more critical on sleeve bushings then it is on sealed ball-bearings. The same is true of packing versus the carbon seal. A wobbling shaft will wallow-out the packing, creating clearance for the coolant to leak past; but the carbon seal can orbit on the face of the impeller and still not leak.

If you are planning to rebuild your own water pump, take the time to read through the shop manual and any instructions that come with the rebuild kit. You need to know what you are getting into before you begin. A water pump is not complicated but it must function properly or your car is likely to have overheating trouble. The only equipment you need beyond basic hand tools is an arbor press. There were special tools used in the dealership specifically for rebuilding the water pump, but the job can be done without them. It simply requires more care on your part, the finished job will be worth the extra time you put into doing it well.

A final thought

The water pump body, backing plate, impeller and shaft must match and should conform to the model year of your vintage Pontiac, not necessarily the year of the engine. This is especially true for the split-head six engines, which apparently had many subtle differences in pump body and impeller style. That is the reason I described where the pump body was in relation to the cylinder head on the ’33 and newer engines. If your original engine is beyond repair, your easiest replacement is one that uses the same water pump mounting. In this way, you should not have any trouble with fan clearance, pulley alignment, hose connections and / or generator mounting. Plus it will be visually “correct”.

There were basically only 5 water pumps; the ‘26-32 split-head six, ’33-36 all, ’37-48 all (except P/6 ’39-40), P/6 ’39-40 and ’49-54 all. The ’32 Pontiac V-8 is so rare it is in a class by itself. The split-head six pumps all use the same mounting gasket, front and rear bushings, packing nut and packing material. From 1933 on with the “packless” pump, there were two seals and two shaft / bearing assemblies. The first seal fits ’33-53, the “54-only seal can actually be used in all pumps back to ’33. There is one shaft/bearing assy. for ’33-48 except P/6 ’39-40 and the another for P/6 ’39-40 plus all ’49-54 models. Based upon coverage like this, we should not have any trouble maintaining our Pontiac water pumps for years to come.

- Home

- ETC Library

- Water Pumps

- Water Pumps Page 2

In 1937 Pontiac cast a new pump body and relocated it on the front of the engine, visually the pump now stood above the cylinder head nearly 2 inches. This was the roller bearing pump I mentioned under Basic Designs. What we have not found yet, is information indicating how long it remained in production. Service parts were available for the roller bearing pump and a quick check shows most of them fit the ’33-’36 pump as well.

The bulletins that follow are both dated October 28th, 1936, fairly early in the ‘37 model year. I checked the engine numbers, over 28,000 sixes and just 1,300 eights were built prior to the problem discussed in the second bulletin.

PS 112, No. 13, October 28, 1936

Leaking Water Pump – 1937 pg.91

“When a leak past the water pump packing on 1937 cars cannot be stopped by tightening the packing nut or replacing the water pump packing, a new Water Pump Assembly Part 499881 should be installed. This part should be ordered direct from your Zone Service Manager.”

PS 112, No. 13, October 28, 1936

Notching Rear Oiler on Water Pump pg.92

“It has been found that the cap on the rear oiler of the water pump, under some conditions, seals the oiler air tight which prevents the oil from entering the bushing. Starting with engine 6-228874 and 8-84301 a small notch is being cut in the rim of the cup which breaks the air tight seal. All 1936 cars having the large oiler at the rear bushing and all 1937 cars bearing an engine number lower than the about should have a small notch cut in the rim of the cup as these cars come in for service.”

The first bulletin states “a new Water Pump Assembly Part 499881” but does not describe any of its features. Presumably any new water pump design underwent a period of extensive testing prior to being approved for production; this bulletin implies to me that one of these new pumps could be made available due to the extenuating circumstance listed. The second bulletin confirms what we already knew; the early ’37 pump was the old fashioned packed-type unit.

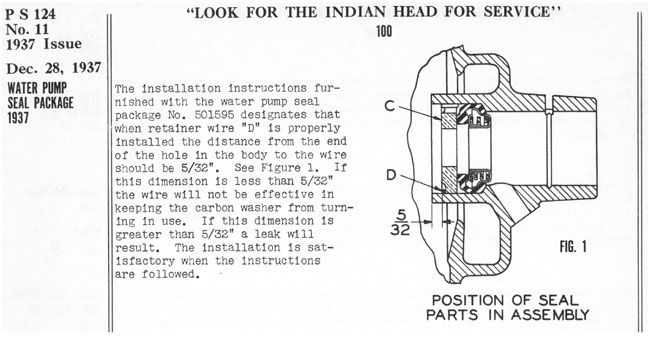

In addition to the service parts for the original equipment 1937 pump, there was a service replacement listed under part number 500804 for the 1937 model year only. This was actually a “package” which also included a new fan. I suspect there was probably a new pulley as well, but I cannot prove that. The 500804 package remained available under its original part number through 1954 at least. Playing the part number game, you will notice that the service bulletin water pump is #499881 and the service replacement package is #500804. This helps us date the second pump package, part numbers were assigned in numerical order and only 923 separate them.