- Home

- ETC Library

- Water Pumps

Pontiac Water Pumps

Arn Landvoigt and I worked on this article for 3 months, and I believe we have learned enough to publish it and get feedback from you on anything that does not ring true. We have had water pump questions in the past and thought it would be helpful to do a comprehensive outline on the subject. We relied heavily on several Pontiac parts books and service bulletins for the information needed, which we cross checked as much as possible. There is conflicting information from factory sources, so our goal is to provide you with as much information as possible and let you apply it to your specific application or situation.

The subject of water pumps is confusing for a number of reasons; not surprising considering the Early Times era covers so many years. We have to contend with the fact that both the factory and aftermarket suppliers provided water pumps for Pontiac automobiles. There is the issue of advancing technology and improved manufacturing techniques, and also the variable of factory service procedures versus how an independent garage would make repairs. A final factor which is often overlooked is the cost in parts and labor of repairing / rebuilding an original unit versus replacing it with a complete new or factory rebuilt assembly.

Basic Designs during the Early Times era

Pontiac water pumps from 1926 through 1936 varied in many aspects but all shared 2 basic features; the shaft ran on bushings and was sealed with packing material retained by an adjustable packing (gland) nut. In 1937 a hybrid water pump was released, it was fitted with a front roller bearing instead of a bushing, but the rear bushing was retained and so was the use of the “packed” seal. In 1938 the water pump was a totally new design using a double ball-bearing assembly to support the shaft, plus a new seal assembly which utilized a spring-loaded carbon seal and secondary rubber shield. This type of pump remained in service through the end of the Early Times era for both six and eight cylinder engines. We have broken down the subject into groups which appear to make the most sense to us, hopefully it will to you too.

First generation pumps

For 1932 and older split-head six models and also the ’32 V-8, Pontiac offered service parts to repair the original water pump as needed. Labor cost was low in relation to parts prices, so naturally repair would be preferred to replacement. Every part of the water pump assembly was available individually, so only those parts needing replacement could be changed. According to the parts information included with this article, there were 5 pump body castings for the split-head six, but only 1 pump to block gasket and 1 each, front and rear bushings; so the differences must have been very subtle. These early “packed” type water pumps are readily identifiable by the packing nut threaded into the end of the housing, through which the shaft protrudes. The other visible clue is the oilers by which the front and rear bushings are lubricated.

Second generation pumps

The straight eight debuted in 1933, the new engine’s water pump retained a packed-type seal and a bushed shaft. The new six cylinder engine was released in 1935 and used the same water pump as the eight cylinder job, a savings for everyone concerned. These early six and eight cylinder engines are visually identifiable by the location of the water pump body, which is even with the top of the cylinder head. This basic water pump design continued through the end of 1936. Pontiac offered individual service parts, just as they had for the first generation pumps; but by 1940 at the latest, they also offered an updated service replacement pump. This complete assembly featured the sealed ball-bearing and carbon seal. The other implication of this service replacement unit was that the O.E. style pump body would no longer be serviced; if it was damaged beyond use the service replacement was to be installed. This obviously means that ’33 to ’36 Pontiac six and eight cylinder cars can now be fitted with either the original equipment “packed” pump or the replacement “packless” one.

Arn Landvoigt and I worked on this article for 3 months, and I believe we have learned enough to publish it and get feedback from you on anything that does not ring true. We have had water pump questions in the past and thought it would be helpful to do a comprehensive outline on the subject. We relied heavily on several Pontiac parts books and service bulletins for the information needed, which we cross checked as much as possible. There is conflicting information from factory sources, so our goal is to provide you with as much information as possible and let you apply it to your specific application or situation.

The subject of water pumps is confusing for a number of reasons; not surprising considering the Early Times era covers so many years. We have to contend with the fact that both the factory and aftermarket suppliers provided water pumps for Pontiac automobiles. There is the issue of advancing technology and improved manufacturing techniques, and also the variable of factory service procedures versus how an independent garage would make repairs. A final factor which is often overlooked is the cost in parts and labor of repairing / rebuilding an original unit versus replacing it with a complete new or factory rebuilt assembly.

Basic Designs during the Early Times era

Pontiac water pumps from 1926 through 1936 varied in many aspects but all shared 2 basic features; the shaft ran on bushings and was sealed with packing material retained by an adjustable packing (gland) nut. In 1937 a hybrid water pump was released, it was fitted with a front roller bearing instead of a bushing, but the rear bushing was retained and so was the use of the “packed” seal. In 1938 the water pump was a totally new design using a double ball-bearing assembly to support the shaft, plus a new seal assembly which utilized a spring-loaded carbon seal and secondary rubber shield. This type of pump remained in service through the end of the Early Times era for both six and eight cylinder engines. We have broken down the subject into groups which appear to make the most sense to us, hopefully it will to you too.

First generation pumps

For 1932 and older split-head six models and also the ’32 V-8, Pontiac offered service parts to repair the original water pump as needed. Labor cost was low in relation to parts prices, so naturally repair would be preferred to replacement. Every part of the water pump assembly was available individually, so only those parts needing replacement could be changed. According to the parts information included with this article, there were 5 pump body castings for the split-head six, but only 1 pump to block gasket and 1 each, front and rear bushings; so the differences must have been very subtle. These early “packed” type water pumps are readily identifiable by the packing nut threaded into the end of the housing, through which the shaft protrudes. The other visible clue is the oilers by which the front and rear bushings are lubricated.

Second generation pumps

The straight eight debuted in 1933, the new engine’s water pump retained a packed-type seal and a bushed shaft. The new six cylinder engine was released in 1935 and used the same water pump as the eight cylinder job, a savings for everyone concerned. These early six and eight cylinder engines are visually identifiable by the location of the water pump body, which is even with the top of the cylinder head. This basic water pump design continued through the end of 1936. Pontiac offered individual service parts, just as they had for the first generation pumps; but by 1940 at the latest, they also offered an updated service replacement pump. This complete assembly featured the sealed ball-bearing and carbon seal. The other implication of this service replacement unit was that the O.E. style pump body would no longer be serviced; if it was damaged beyond use the service replacement was to be installed. This obviously means that ’33 to ’36 Pontiac six and eight cylinder cars can now be fitted with either the original equipment “packed” pump or the replacement “packless” one.

Third generation pumps

In 1938 the location remained the same, but the pump was redesigned as already described with a sealed ball-bearing and carbon seal assembly. Although there were numerous subtle changes and various service parts listed for use; it remained essentially unchanged through 1948 with 1 notable exception. The 1939/40 six cylinder engines used a unique water pump. This was due to the fact that either engine was available in the Deluxe Series 26 or 28 models riding on the same 120” wheelbase. Prior to this, the six cylinder models were always shorter from the cowl forward, maintaining the relationship between fan and radiator with the shorter six cylinder engine.

In 1941, with the advent of the “engine option”, Pontiac mated fan shrouds with the six and eight cylinder engines, thus eliminating the fan clearance issue regardless of which Series car the engine was installed in.

In 1938 the location remained the same, but the pump was redesigned as already described with a sealed ball-bearing and carbon seal assembly. Although there were numerous subtle changes and various service parts listed for use; it remained essentially unchanged through 1948 with 1 notable exception. The 1939/40 six cylinder engines used a unique water pump. This was due to the fact that either engine was available in the Deluxe Series 26 or 28 models riding on the same 120” wheelbase. Prior to this, the six cylinder models were always shorter from the cowl forward, maintaining the relationship between fan and radiator with the shorter six cylinder engine.

In 1941, with the advent of the “engine option”, Pontiac mated fan shrouds with the six and eight cylinder engines, thus eliminating the fan clearance issue regardless of which Series car the engine was installed in.

Fourth generation pumps

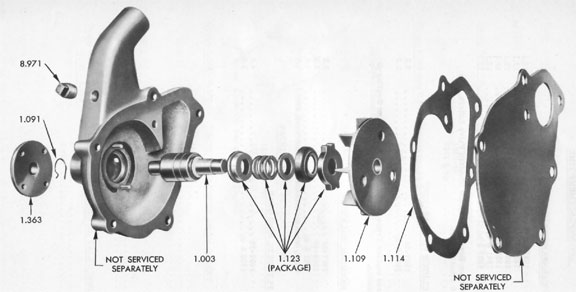

In 1949 with the advent of the first true post-war bodies for Pontiac, the water pump location changed again. The top of the pump body was now about level with the deck of the block, (the mounting surface for the cylinder head). The body casting was again new, but the shaft/bearing and the seal assemblies were not. The shaft and bearing assembly had previously been used in the 1939/40 six cylinder pump, while the seal carried over from the third generation pump.

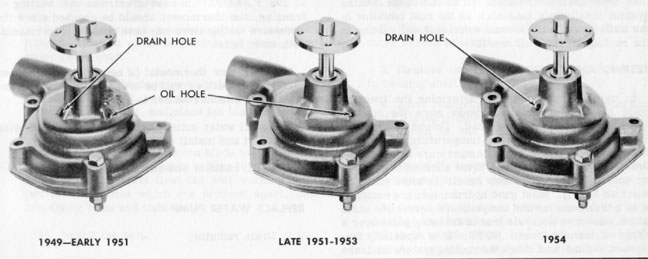

The ’49 to early ’51 pump featured a spring clip shaft and bearing retainer inserted in a slot in the pump snout, plus both oil and drain holes where the snout met the pump body. The late ’51 through ’53 pump eliminated the spring clip retainer by the simple expedient of reducing the bore diameter so the bearing had to be pressed into the housing. The drain hole was also eliminated, but not the oil hole. There was a late ’53 water pump unique to Powerglide equipped cars; these featured an additional inlet hole for the transmission oil cooler. The 1954 pump eliminated the oil (vent) hole, but the drain hole returned. A new one-piece seal was designed for ’54 cars to withstand the 13 psi pressure cap installed on air conditioned models. This revised pump was installed on all ’54 automobiles, with or without air conditioning. In late 1954 a Hydra-Matic oil cooler package was released by Pontiac for police, taxi and rural mail carriers. This kit included a specific water pump with additional fittings listed under part number 520927.

In 1949 with the advent of the first true post-war bodies for Pontiac, the water pump location changed again. The top of the pump body was now about level with the deck of the block, (the mounting surface for the cylinder head). The body casting was again new, but the shaft/bearing and the seal assemblies were not. The shaft and bearing assembly had previously been used in the 1939/40 six cylinder pump, while the seal carried over from the third generation pump.

The ’49 to early ’51 pump featured a spring clip shaft and bearing retainer inserted in a slot in the pump snout, plus both oil and drain holes where the snout met the pump body. The late ’51 through ’53 pump eliminated the spring clip retainer by the simple expedient of reducing the bore diameter so the bearing had to be pressed into the housing. The drain hole was also eliminated, but not the oil hole. There was a late ’53 water pump unique to Powerglide equipped cars; these featured an additional inlet hole for the transmission oil cooler. The 1954 pump eliminated the oil (vent) hole, but the drain hole returned. A new one-piece seal was designed for ’54 cars to withstand the 13 psi pressure cap installed on air conditioned models. This revised pump was installed on all ’54 automobiles, with or without air conditioning. In late 1954 a Hydra-Matic oil cooler package was released by Pontiac for police, taxi and rural mail carriers. This kit included a specific water pump with additional fittings listed under part number 520927.